Servo energy-saving injection molding machine

Product details

1. Product introduction

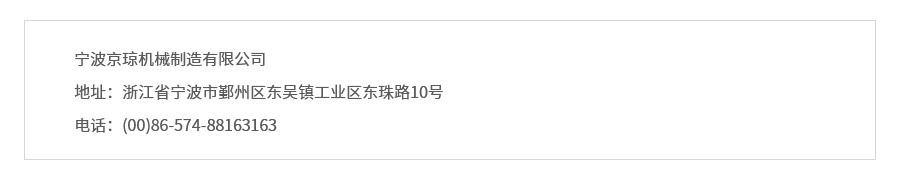

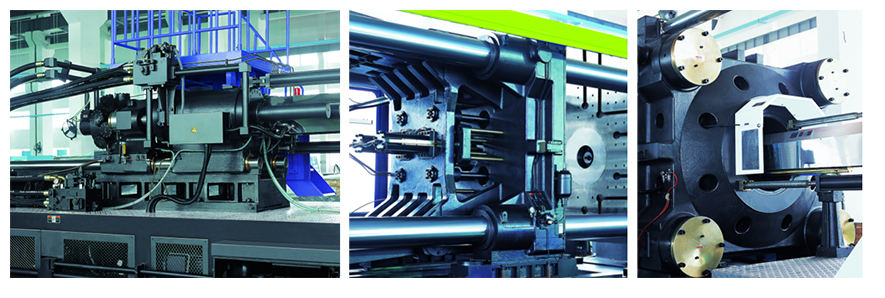

(1) The machine is equipped with a double cylinder balanced injection device and high plasticizing screw configuration;

(2) High response hydraulic control system to meet the needs of various products;

(3) The template adopts the classic 5-point hyperbolic elbow design, which has stronger rigidity and more accurate precision control;

(4) Differentiated appearance styles can be customized according to customer needs.

2. Technical specifications

Product specification: NHTX68-NHTX3000

Injection weight (ps) :61g-40000g

Closing force:680KN-30000KN

Tie rod spacing (width * height) :310mm×310mm-1900mm×1750mm

Machine weight:2.5t-200t

3.Live video

4. Machine parts

5.Process samples

6.Industrial use

The servo energy-saving precision injection molding machine produced by the company has a very wide range of uses, can be used in daily necessities, household appliances, electronic equipment, auto parts and other industries.

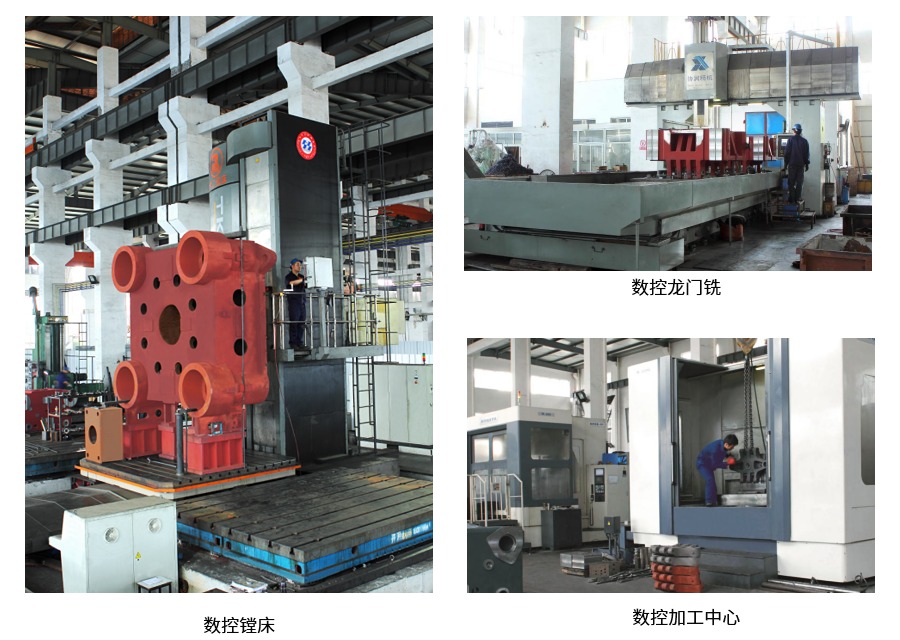

7.Production Equipment

The company has a group of experienced high quality technical personnel, at the same time equipped with CNC gantry milling, CNC boring machine, CNC machining center and other kinds of production and processing equipment, advanced technology, reliable quality, products sold in domestic cities and overseas more than 10 countries and regions.

8.Manufacturer advantage

9.Service support

10.Cooperative partner

11.Certificates

12.Company profile

13.Contact information